Product Detailed Specification

|

Grade

|

Grade 1

|

Grade 2

|

Grade 5

|

Grade7

|

Grade 9

|

Grade 12

|

|

Alloy

|

Commercially pure

|

Commercially pure

|

Ti-6Al-4V

|

Ti-0.15Pd

|

Ti-3Al-2.5V

|

Ti-0.3Mo-0.8Ni

|

|

DIN

|

3.7025

|

3.7035

|

3.7164/5

|

3.7235

|

3.7195

|

3.7105

|

|

UNS

|

R50250

|

R50400

|

R56400

|

R52400

|

R56320

|

R53400

|

Standard: GB/T 16598-1996; ASTM B348,ASTM B381,AMS 4928.

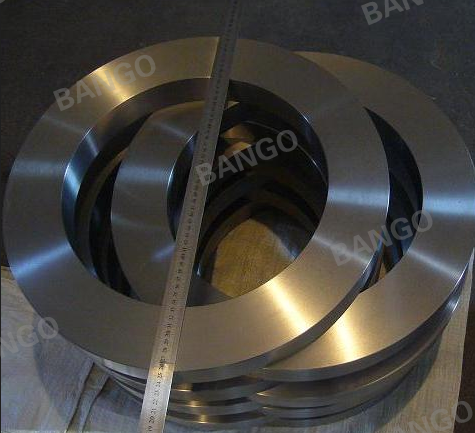

Specification:

|

OD(mm)

|

ID(mm)

|

Thickness(mm)

|

|

200~400

|

100~300

|

20~120

|

|

400~700

|

150~500

|

40~250

|

|

700~1500

|

300~1200

|

40~600

|

Process technology: Forging, die forging, rotary forging, fine forging, welding

Test: Tensile strength test, hardness test, chemical composition test, ultrasonic test, radiographic test, osmotic coloring test.

Surface treatment: Auto finish, chamfering.

Surface quality: Ra value of two end surfaces should be no more than 3.2l displacement m(subject to the requirement of ultrasonic testing), the surface roughness Ra of the inner and outer surface should be no more than 12.5mm (Ra should be no more than 3.2mm when the outer circumference surface needs to be ultrasonic testing), and the chamfering radius should be 5 ~ 15mm.

Application field: Aerospace, aviation, military, light industry, chemical industry, textile, medical and petrochemical industries.